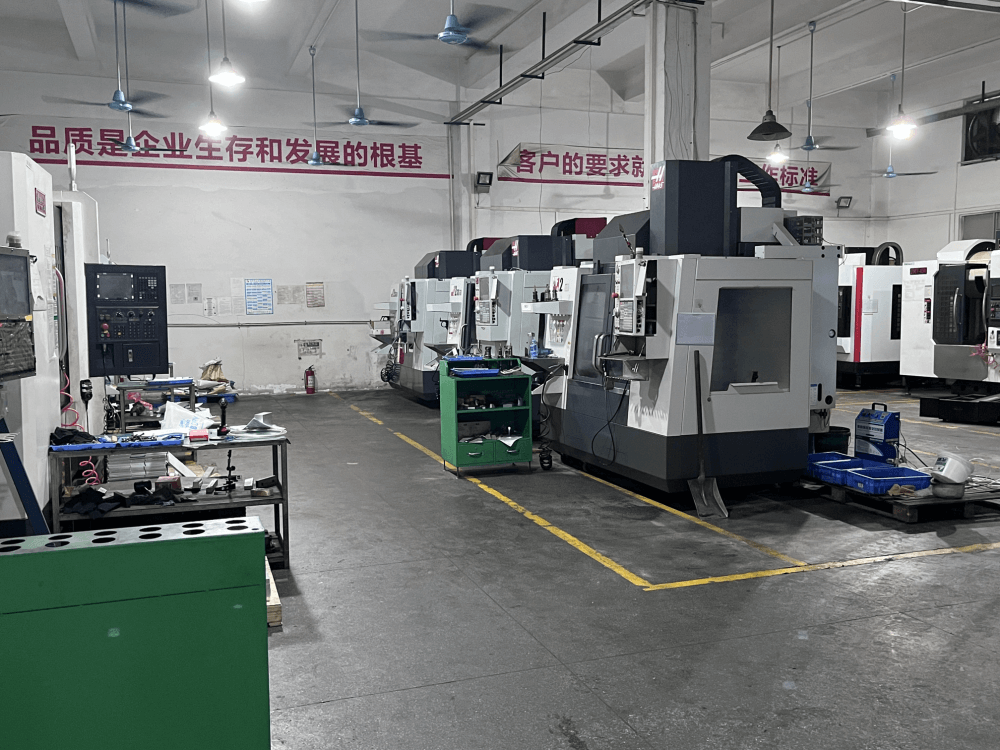

CNC Machining Service

Customized manufacturing solutions for CNC machined parts.

Catering to one-off prototypes as well as full-scale mass production.

Get in touch with us today to request a quote for our CNC machining services.

What Is CNC Machining ?

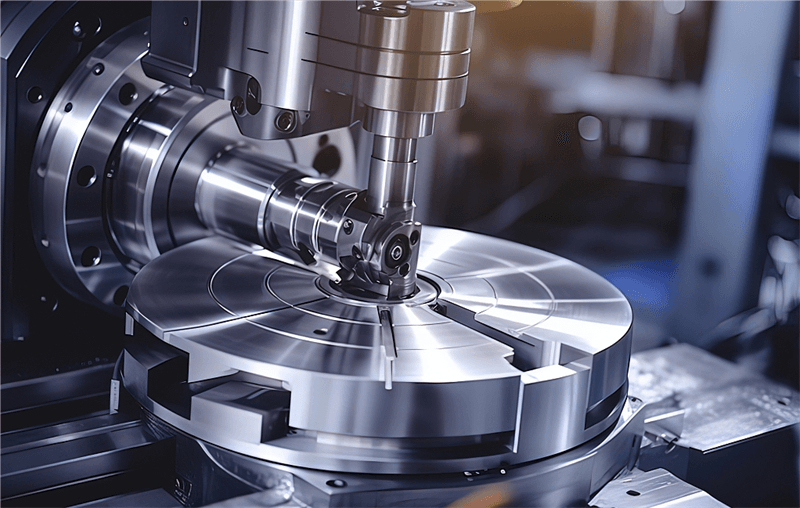

CNC Machining is a computer-controlled process that involves the removal of material from a workpiece.

This method is highly efficient, accurate, and fast compared to traditional machining techniques.

What Is CNC Machining Used For?

At Kachi, we offer precision CNC machining services for the production of complex finished parts, components, and tools for plastic injection molding or pressure die casting. Additionally, CNC manufacturing is utilized for secondary drilling, tapping, and milling operations on machined parts or parts made from other processes. Our team uses a variety of specialized CNC machine tools to perform various operations on raw stock, but CNC mills are the most commonly used and versatile multi-axis machines in our daily operations.

Our CNC Service

Kachi provides custom CNC milling and lathe services.

Learn more about what services we offer.

CNC Turnign Services

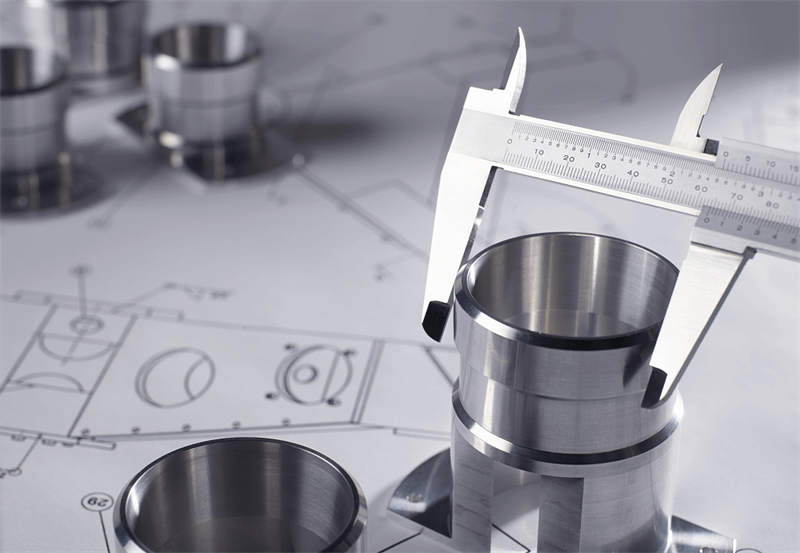

The general process of turning involves rotating a part while a single-point cutting tool is moved parallel to the axis of rotation. Turning can be done on the external surface of the part as well as the internal surface (the process known as boring). The starting material is generally a workpiece generated by other processes such as casting, forging, extrusion, or drawing.

CNC Milling Services

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done by varying directions on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations. It is one of the most commonly used processes for machining custom parts to precise tolerances.

Guidelines and functions for CNC milling

Our fundamental principles encompass vital design factors aimed at enhancing manufacturability, improving appearance, and decreasing overall production time.

Capability Equipment Section Turning

Our CNC turning process is highly efficient and allows us to produce custom prototypes and final parts in as little as one day. We use state-of-the-art CNC lathes equipped with power tools to machine a wide range of features such as axial and radial holes, flats, grooves, and slots.

CNC tuning is typically used in a variety of scenarios, including:

- Manufacturing parts for functional prototypes and final products

- Creating parts with cylindrical features

- Producing parts with axial and radial holes, flats, grooves, and slots

Our team of experienced engineers and machinists work closely with clients to ensure that their parts are machined to their exact specifications. We use the latest software and tools to program our machines, ensuring that every part is manufactured with precision and accuracy.

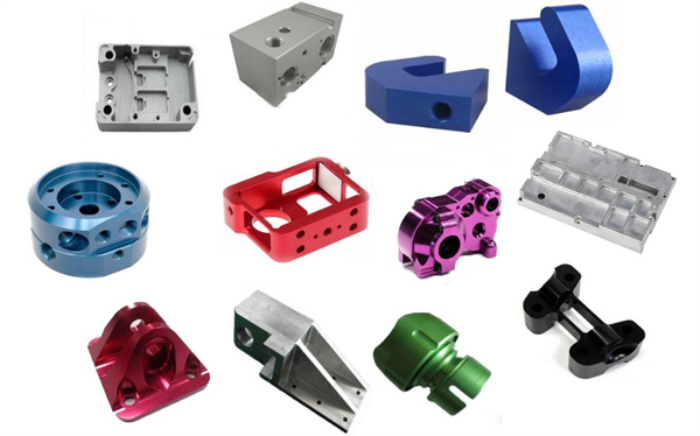

Once the machining process is complete, our parts undergo rigorous quality checks to ensure that they meet our high standards of quality and consistency. We also offer a range of finishing options, including anodizing and chrome plating, to give our parts a professional and polished look.

At our facility, we are committed to providing our clients with the highest quality parts and services. Whether you need a single prototype or a large production run, we have the expertise and capabilities to meet your needs.

Design Guidelines for CNC Turning

Our guidelines improve part manufacturability and decrease production time.

| Maximum Dimensions | Diameter | 100.33mm |

| Length | 228.6mm | |

| Minimum Dimensions | Diameter | 4.07mm |

| Length | 1.27mm | |

| Wall Thickness | 0.51mm | |

| Angle | 30° | |

| Tolerances | +/- 0.13mm |

Surface finishing involves the process of altering a metal’s surface through reshaping, removing or adding, and is used to measure the overall texture of a surface characterized by:

Lay – The direction of the predominant surface pattern (often determined by the manufacturing process). Waviness – Pertains to fine detail imperfections or coarser irregularities, such as surfaces that are warped or deflected from specifications.

Lay – The direction of the predominant surface pattern (often determined by the manufacturing process). Waviness – Pertains to fine detail imperfections or coarser irregularities, such as surfaces that are warped or deflected from specifications.

Advantages of Metal Surface Finishing Process

The functions of metal surface treatment can be summarized as follows:

-Improve parts appearance

-Add specific beautiful colors

-Change the luster

-Enhance chemical resistance

-Increase wear resistance

-Limit the effects of corrosion

-Reduce friction

-Remove surface defects

-Cleaning the parts

-Serves as a primer coat

-Adjust the sizes

Kachi CNC Machining Service FAQ

We are a great CNC machining service provider in terms of experience, expertise and reputation.

CNC machines can work with a wide range of materials, including metals (such as aluminum, brass, and steel), plastics (such as ABS, nylon, and polycarbonate), and wood.

The time it takes to produce parts with CNC machining depends on several factors, including the complexity of the part, the type of material used, and the size of the order. In general, however, CNC machining is a relatively fast process.

The cost of CNC machining varies depending on several factors, including the complexity of the part, the type of material used, and the size of the order. In general, however, CNC machining is a cost-effective way to produce high-quality parts and products.

Our CNC machining is capable of achieving standard tolerances of 0.05 microns for most commercial and industrial applications. If you require tighter tolerances for special projects, please feel free to contact us for professional consulting services.

Reasons For Choosing Our Services

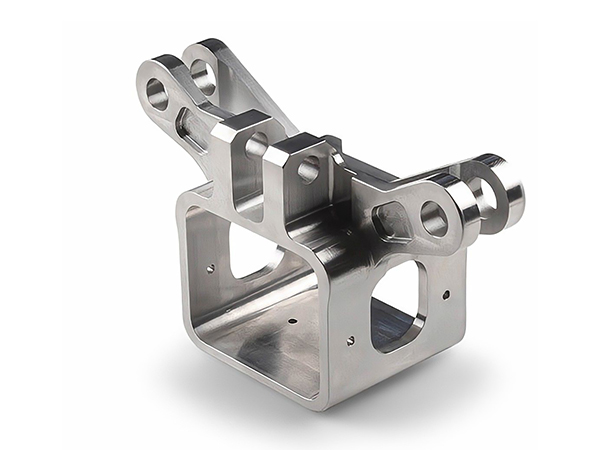

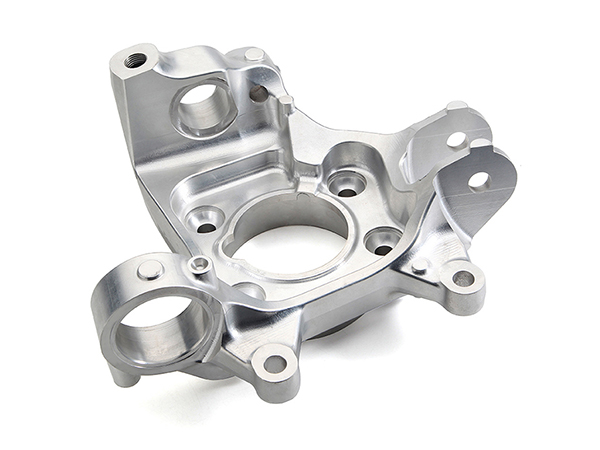

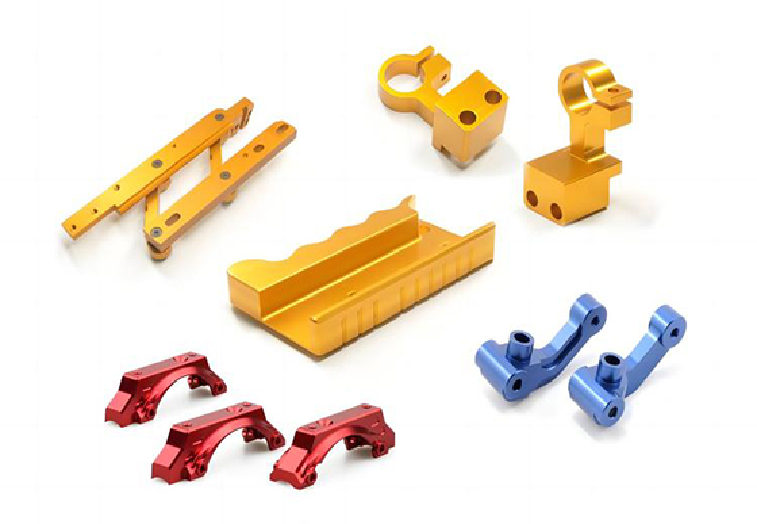

Precision CNC Machined Parts Showcase

Explore our extensive gallery of high quality prototypes and parts showcasing custom products made by my esteemed customers